Severe service Qtr. turn & rising stem ball valves

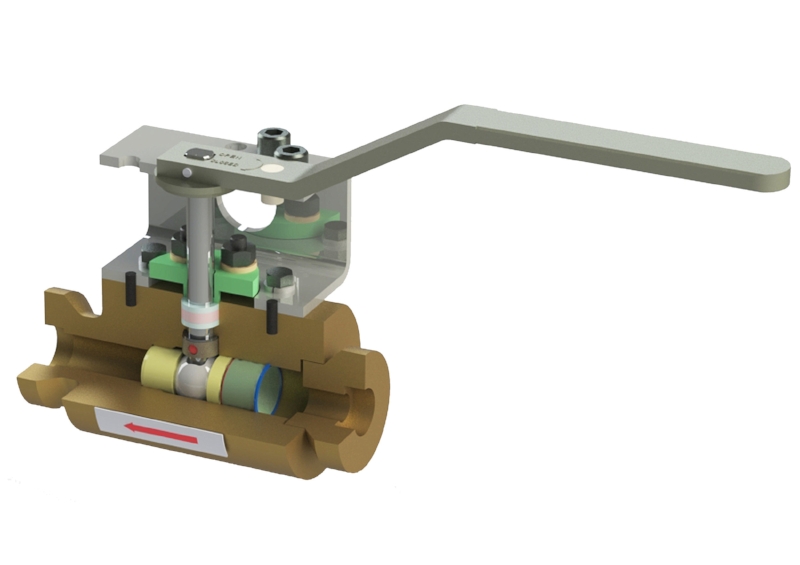

Z1 Unibody Power Valve

The Z1 Unibody Power Valve is a one-piece metal-seated ball valve engineered for clean steam severe-service (high-pressure, high-temperature) environments, including power generation and critical on/off applications.

- 0.65" to 3.00" Bore sizes

- 0.75" to 2.50" NPS SWE; 0.75" to 4.00" NPS BWE

- 150 to 4500# ANSI classes

- Design meets ASME TDP-1 2006 bore requirements

- Materials: A105, F22, F91, and 316SS

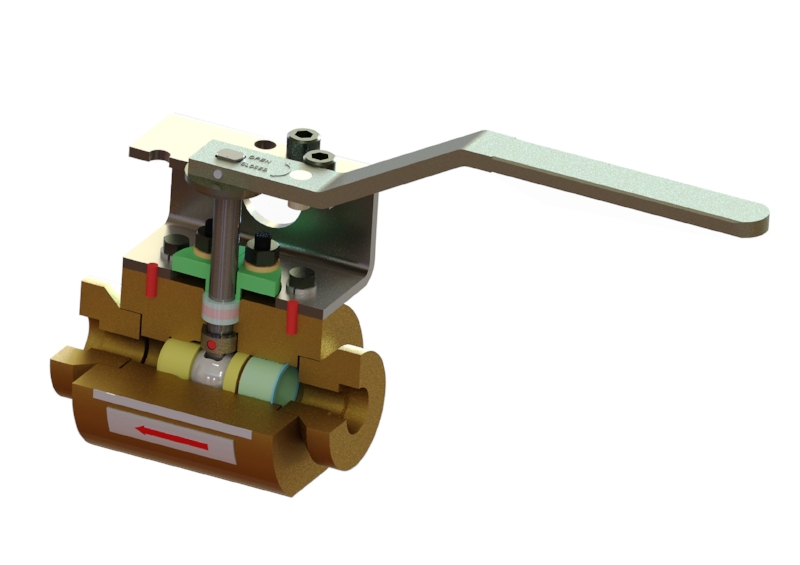

Z1-LW Lightweight Unibody Power Valve

The Z1-LW is a one-piece lightweight ball valve designed for clean steam severe-service (high-pressure, high-temperature) environments. With one integral SW end, the compact design of the Z1-LW valve weighs 50% less than typical flanged valves of the same pressure class.

- 0.65" to 1.00" Bore sizes

- 0.75" to 1.00" NPS SWE

- 150 to 1500# ANSI classes

- Design meets ASME TDP-1 2006 bore requirements

- Materials: A105, F22, F91, and 316SS

Z2 Two-Pieve Isolation Valve

The Z2 is a two-piece metal-seated ball valve engineered for severe-service environments for use in critical applications, including chemical / petro-chemical, refining, power, and mining.

- 0.50" to 24.00" NPS

- 150 to 2500# ANSI classes

- Full and reduced ports

- Uni or bi-directional seals

- Material: A105, F22, F91, 316SS, and exotics

- Firesafe design meets API 607 or API 6FA

- SIL-3 certification, per IEC 61508:7 2010

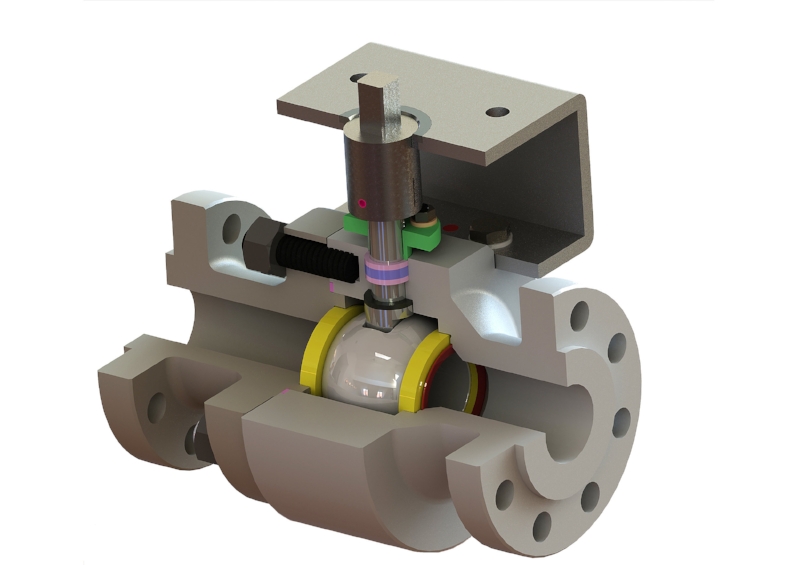

Z4 Rising Stem Ball Valve

The Z4 Rising Stem Ball Valve employs a tilt-and-turn design enabling frequent cycling, zero-leakage, and low torque operation. This valve is engineered to replace traditional ball, gate, and plug valves in gas processing plants using molecular sieve systems for switching service, pipelines, gas transmission, and other high performance applications requiring frequent cycling with positive shutoff operation.

- 1.00" to 24.00" Bore sizes

- 150 to 2500# ANSI classes

- Bonnet: Enclosed or OS&Y

- Soft or metal-seated

- Available in custom configurations (bonnet styles, sealing element materials, etc.)